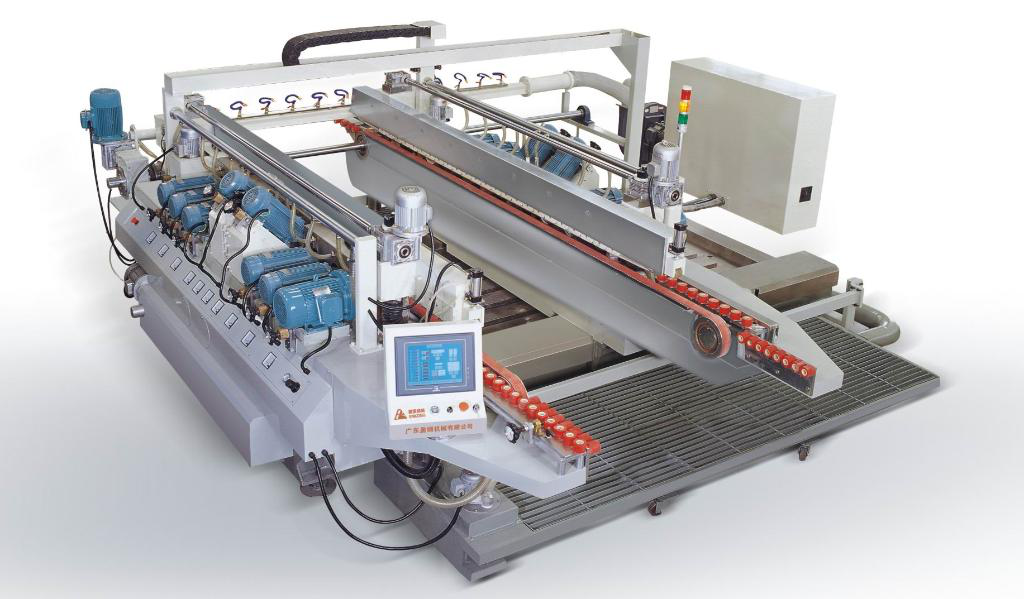

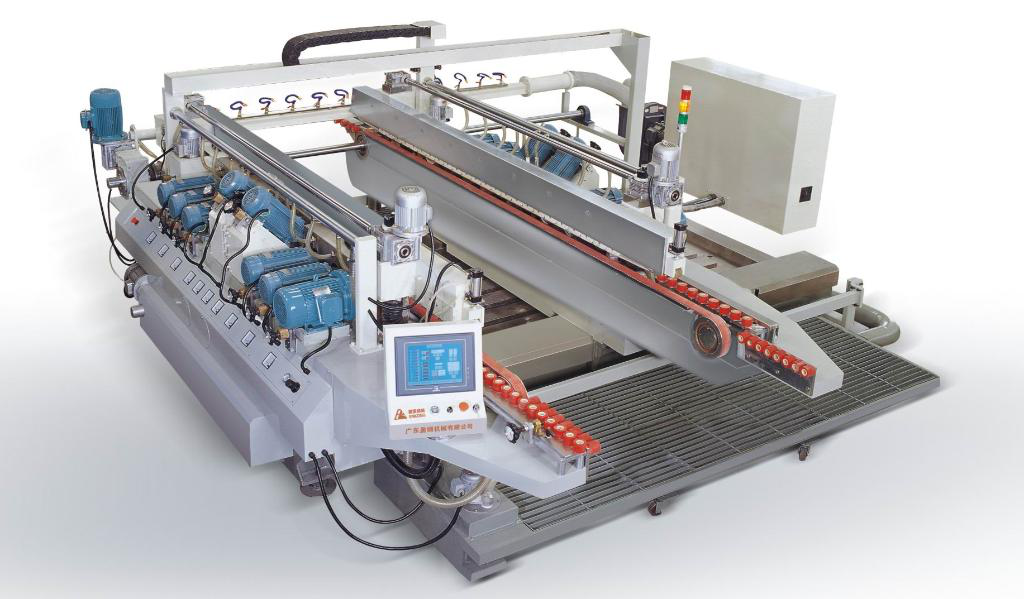

1. Components: Conventional single-sided glass edge grinder is generally composed of main machine (base + pillar + front and rear beams + fan + grinding wheel water tank + motor + electric box, etc.), guide rail at input and outlet end, glass support frame and floor water tank.

2.

Working Principle: Glass edge grinder mainly realizes glass grinding and polishing through grinding head motor and grinding wheel. Ordinary one-sided/two-sided edge grinder can realize rough grinding, fine grinding and polishing at one time. Customers can choose different grinding wheels according to their own processing requirements.

Application of High Pressure Fan:

The main function of high-pressure fan in glass edge grinding equipment is to adsorb and fix the glass and to drive water by the wind knife. The suction generated by the fan forms negative pressure on the conveyor belt of the equipment, so that the glass is adsorbed and fixed on the conveyor belt without deviation and correct edge grinding. The positive pressure produced by the fan is connected to the blade to form a blowing force, which plays the role of catching up water to the waste trough on the glass edge and preventing the splashing of cleaning water when the glass edge is grinded.

Cautions for the Use of Fans in Glass Edge Grinding Machines:

1. After installation and commissioning, please check the fan running current to ensure that the fan runs within the rated current and avoid overload operation.

2. Check and measure the three-phase power supply and electrical components regularly, tighten the connection of the fan power supply, and avoid the fault of the fan caused by the lack of phase operation.

3. It is suggested that filters be installed and cleaned regularly to avoid long-term work, which results in dust blocking and over-load operation of the system. Generally, the system should be cleaned up once a week or two weeks. According to the working conditions, the filter element should be replaced after three months of use, and the filter element should be replaced for up to six months. The cleaning and maintenance of the filter element can only use compressed air blowing.

4. It is suggested that the pressure relief valve be installed correctly so as to protect the high-pressure fan and prevent the fan from blocking the load operation.

5. Regarding the temperature of the fan, please ensure that the ambient temperature and the intake temperature of the fan are less than 50 degrees, the surface temperature of the motor is less than 70 degrees, and the surface temperature of the pump body is less than 100 degrees.

6. See the instructions for use in detail.