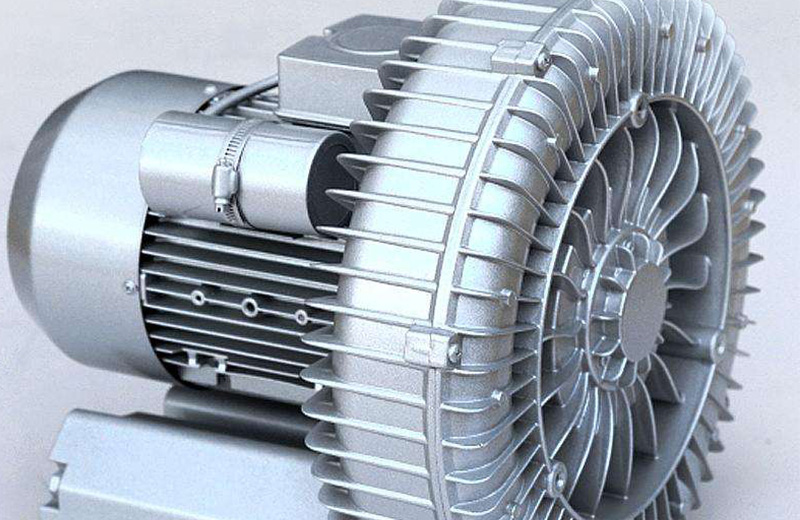

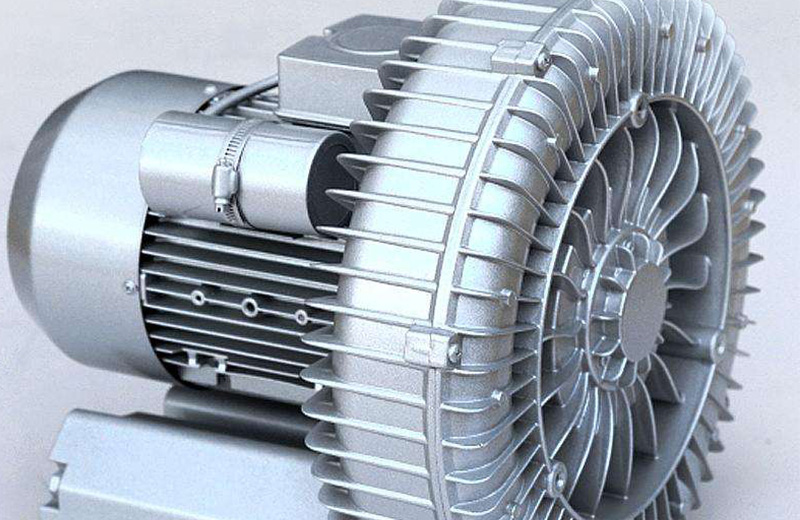

Gas booster transmission high-pressure blower. In some customers' working conditions, gas booster vortex blower is often used in comparison of laboratory devices, combustion machines and ignition equipment. It can realize the pressurized transmission of nitrogen, oxygen or other gases to meet the use requirements.

The vacuum blower for gas transmission are mainly divided into the following points:

1. Simple gas transmission: some companies need to increase the pressure of the gas transmission in order to overcome the resistance of the pipeline. In this case, the pressure is generally not high. Because the pressure loss of a single pipeline is limited, but the amount of gas transmission is often large, and the air power required is often quite large.

2. Production of high pressure gas: in chemical industry, some chemical reaction processes need to be carried out under high pressure, such as ammonia synthesis reaction and ethylene bulk polymerization; some separation processes also need to be carried out under high pressure, such as gas liquefaction and separation. These high-pressure processes put forward quite high requirements for the outlet pressure of related gas transmission equipment.

3. Production vacuum: quite a lot of unit operations are carried out under the condition of lower than atmospheric pressure. At this time, the vacuum pump is required to extract gas from the equipment to generate vacuum.

At present, the gas conveying fan is widely used in the ventilation, dust removal and cooling of factories, mines, tunnels, cooling towers, vehicles, ships and buildings; the ventilation and induced draft of boilers and industrial furnaces; the cooling and ventilation of air conditioning equipment and household electrical equipment; the drying and selection of grains; the air source of wind tunnels and the inflation and propulsion of hovercraft.

Because of the small density of gas, its volume flow is very large. Therefore, the velocity in the gas delivery pipe is much larger than that in the liquid, and the economic velocity in the front (15-25m / s) is about 10 times of the latter (1-3m / s). In this way, the resistance loss of gas is about 10 times of that of liquid after delivering the same mass flow rate at their respective economic flow rate and passing through the same pipe length. Therefore, the power consumption of gas transmission equipment is often very large. Because of the compressibility of the gas, the volume and temperature will change with the change of the gas pressure inside the conveying machine. These changes have a great influence on the structure and shape of gas conveying equipment. Therefore, the gas transmission equipment needs to be classified according to the outlet pressure.