Understanding IE Efficiency Motor Levels

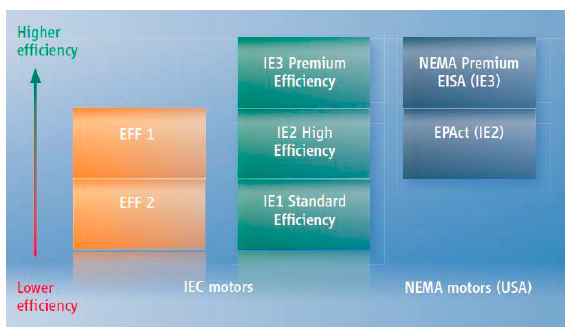

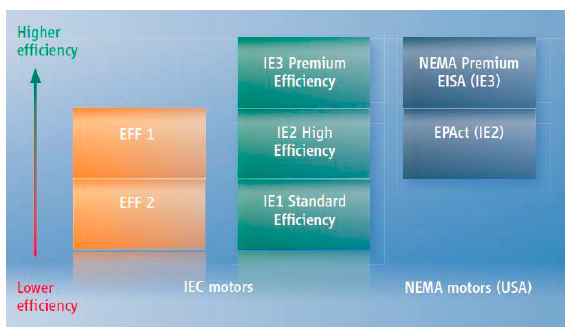

The International Efficiency (IE) classification system for electric motors defines distinct efficiency levels. These levels help standardize energy efficiency, allowing industries to select motors that align with energy-saving goals. The classifications range from IE1 to IE5, with each level indicating progressively better efficiency:

-

IE1 (Standard Efficiency): The base efficiency level, often outdated in modern industrial settings.

-

IE2 (High Efficiency): A more energy-efficient alternative to IE1, often the minimum standard in many regions.

-

IE3 (Premium Efficiency): Designed to deliver significant energy savings and lower operational costs.

-

IE4 (Super Premium Efficiency): Provides even greater efficiency and savings.

-

IE5 (Ultra-Premium Efficiency): Represents the pinnacle of energy-saving technology, primarily for cutting-edge applications.

Key Differences Between IE2 and IE3 Motors

Efficiency Gains with IE3 Motors

IE3 motors are notably more efficient than their IE2 counterparts. This higher efficiency is achieved through improved materials, better manufacturing processes, and optimized designs.

-

Energy Consumption: IE3 motors consume less electricity for the same output, leading to reduced operational costs.

-

Thermal Performance: Lower heat generation due to higher efficiency reduces wear and tear, increasing motor lifespan.

-

Environmental Impact: The reduced energy demand of IE3 motors contributes to lower carbon emissions.

Design Enhancements

IE3 motors typically feature:

-

Superior Windings: Minimized energy losses due to resistance.

-

Enhanced Magnetic Circuits: Better magnetic flux management for efficient performance.

-

High-Quality Bearings and Materials: Ensuring durability and reliability under industrial loads.

Operational Standards and Compliance

Many countries and regions mandate the use of IE3 motors for new installations. For instance:

-

European Union: IE3 is the standard for motors between 0.75 kW and 375 kW.

-

United States: IE3 motors comply with the Department of Energy's efficiency regulations.

-

China: IE3 efficiency levels are promoted under the "China Energy Label" system.

Advantages of IE3 Motors for Side Channel Blowers

Increased Efficiency in Airflow Generation

IE3 motors enhance the performance of side channel blowers by providing higher energy efficiency, reducing power consumption during operation. This makes them ideal for continuous applications requiring stable and efficient airflow, such as:

-

Industrial drying systems.

-

Pneumatic conveying systems.

-

Aeration in wastewater treatment.

Improved Durability and Reliability

The robust construction of IE3 motors reduces the risk of overheating, ensuring that side channel blowers operate reliably even under demanding conditions. This minimizes downtime and maintenance costs while extending the lifespan of the blower system.

Conclusion

Investing in IE3 motors represents a strategic move for businesses aiming to enhance energy efficiency, reduce costs, and meet sustainability goals. These motors not only outperform IE2 in terms of efficiency and reliability but also position companies as leaders in adopting environmentally conscious technologies. The transition to IE3 motors is not just an upgrade—it's a commitment to operational excellence and a sustainable future.