Side channel blowers require a different type of motor compared to regular motors to meet the specific requirements of the high-pressure application. Here are some potential differences between the motors used in side channel blowers and regular motors:

Rated power and speed: side channel blowers typically require higher rated power and speed. These fans need to generate higher air pressure and airflow, requiring the motor to deliver sufficient power and speed to meet these demands. In contrast, regular motors usually have lower power and speed, suitable for more conventional applications.

Insulation rating: Since side channel blowers often operate in industrial environments, their motors need to have higher insulation ratings. This is necessary to withstand harsh working conditions and environments, ensuring the safe and reliable operation of the motor. The motor used in side channel blowers typically undergoes insulation testing and certification to meet safety requirements.

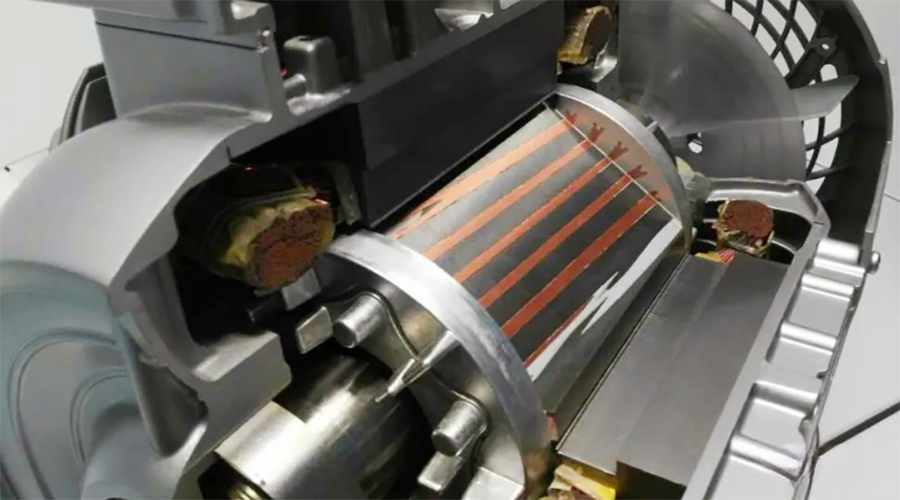

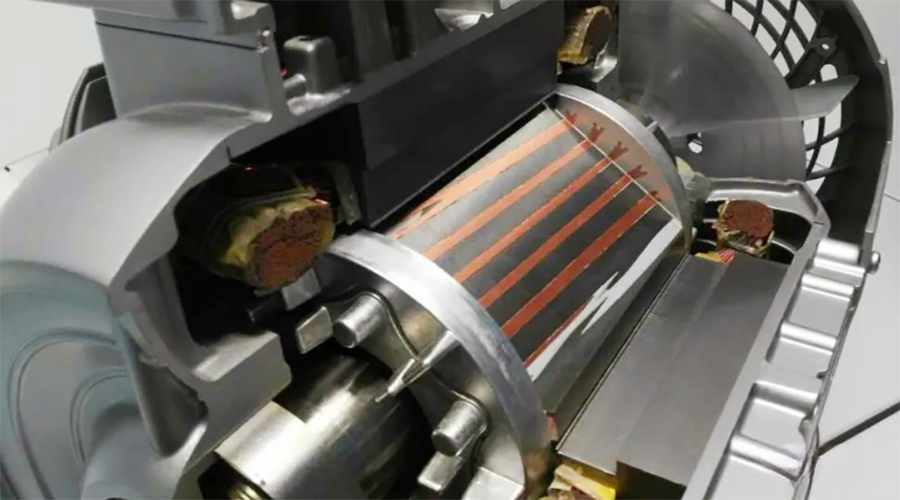

Heat dissipation design: side channel blowers' motors typically require better heat dissipation design. Operating under high loads and continuous operation, these motors generate more heat. Therefore, the motor's cooling system needs to have a larger heat dissipation surface area, better airflow design, or other cooling measures to effectively cool the motor and maintain its normal operating temperature.

High-temperature resistance: The motors used in side channel blowers may need to be designed to withstand high temperatures. This is because these fans may handle high-temperature gases or operate in high-temperature environments. The motor's insulation materials, cooling systems, and other critical components need to be able to withstand high temperatures to ensure the motor's reliability and longevity.

Corrosion resistance and protection: side channel blowers often handle media containing corrosive gases or particles, requiring the motor to have better corrosion resistance and protection. This may involve using corrosion-resistant materials for key motor components such as the housing, bearings, and seals. Additionally, the motor may require a higher protection rating to prevent the ingress of external moisture, particles, or other harmful substances.

In summary, the motors used in side channel blowers differ from regular motors in terms of power, speed, insulation rating, heat dissipation design, high-temperature resistance, and corrosion resistance. These differences are necessary to ensure the reliable operation of side channel blowers under high-pressure conditions and challenging environments.