The side channel blower stands out from traditional fans primarily due to its ability to generate much higher pressure. While traditional fans are designed to move large volumes of air with low pressure, side channel blowers focus on producing moderate airflow with significantly higher pressure.

The most notable difference lies in the pressure levels. Side channel blowers can reach pressures as high as 3000 mbar (43.5 psi), whereas conventional fans usually operate at pressures below 100 mbar. This makes side channel blowers more suitable for applications that require a strong, directed airflow rather than just moving air across a space.

While traditional fans excel in generating large volumes of airflow at low pressure, side channel blowers deliver high pressure at a more modest flow rate. This balance between airflow and pressure is vital for applications that require forceful, concentrated airflow rather than sheer volume.

Despite their impressive pressure capabilities, the airflow of side channel blowers is somewhat limited due to their size and structural design. Typically, the maximum airflow generated by a side channel blower is around 3000 m³/h. However, this figure can vary depending on the specific model and application requirements.

The compact design of the side channel blower, while optimized for pressure, limits its ability to move large amounts of air. The internal rotor and side channels compress the air to create high pressure, but the overall volume of air moved remains constrained by the blower’s design and size.

As the pressure increases, the flow rate tends to decrease. The ability of side channel blowers to achieve pressures around 3000 mbar comes at the expense of airflow. This trade-off, however, is beneficial in applications where pressure is critical, even if the airflow volume is moderate.

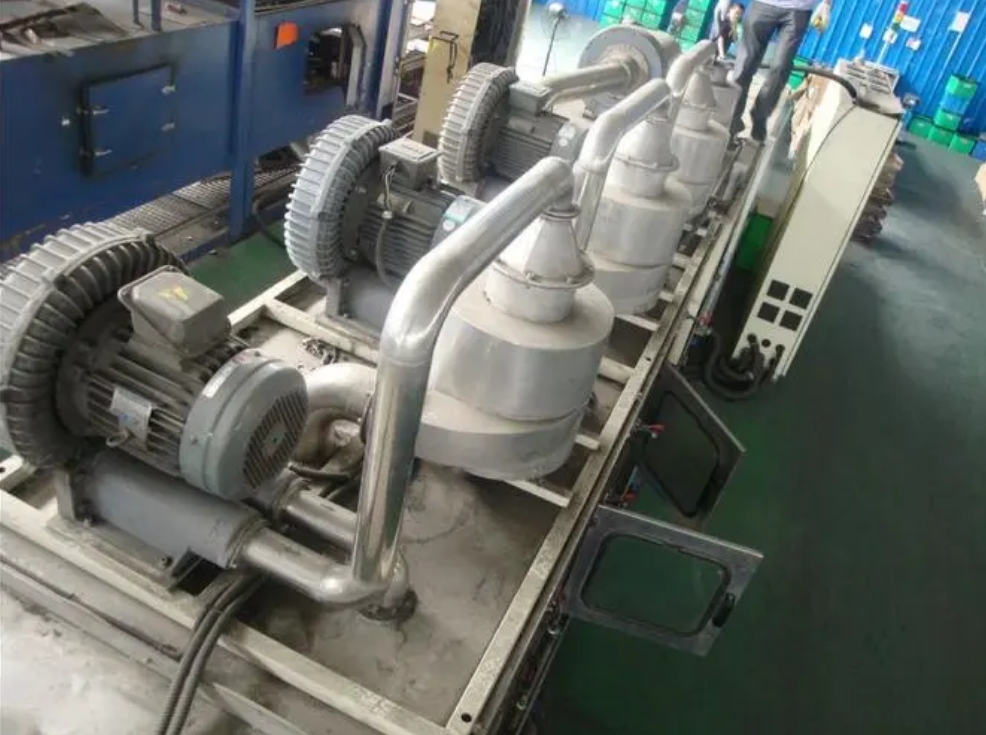

The unique combination of high pressure and moderate airflow makes side channel blowers well-suited for various industrial applications where forceful airflow is essential. Some of these applications include:

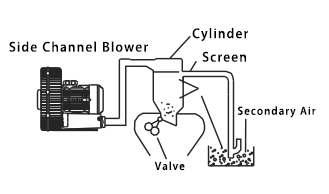

In industries that require pneumatic conveying, such as moving powders, granules, or other small materials, side channel blowers provide the necessary pressure to transport these materials over long distances. The blower’s ability to maintain steady pressure ensures efficient material flow, even if the volume of air is lower than other fan types.

Side channel blowers are ideal for vacuum applications. Their high-pressure capabilities allow them to generate suction power needed for tasks such as packaging, lifting, or removing air from closed environments. The blower’s ability to produce a strong vacuum makes it indispensable for industries like packaging, electronics, and laboratory equipment.

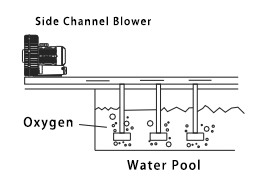

In water treatment plants, side channel blowers are used for aeration processes. They introduce high-pressure air into wastewater, helping to oxygenate the water and promote the breakdown of organic materials. The blower’s ability to maintain consistent pressure makes it a reliable choice for these environments, where effective aeration is crucial.

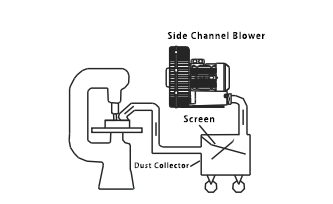

For industrial processes that produce dust or harmful fumes, side channel blowers play a critical role in extraction systems. Their high pressure allows them to effectively remove particles and contaminants from the air, ensuring a safe and clean working environment.

In the medical and laboratory fields, side channel blowers are used for equipment that requires precise airflow control. Applications like sterilization equipment, respiratory machines, and laboratory airflow chambers depend on the consistent and controllable airflow provided by side channel blowers.

The side channel blower is distinguished by its ability to provide high pressure with moderate airflow, making it a vital tool in industries that require forceful, directed airflow. With pressure levels reaching up to 3000 mbar, the side channel blower is ideal for applications like pneumatic conveying, vacuum generation, aeration, and dust extraction. Though its airflow volume is more limited than traditional fans, the blower's high-pressure capabilities make it an essential component in a variety of industrial processes.