The rubber products industry encompasses a variety of processes to manufacture items ranging from tires and seals to gaskets and flooring. These processes require precise control of materials and environmental conditions to ensure product quality and efficiency. Key processes include:

Compounding is the initial phase where raw rubber is mixed with various additives, such as accelerators, fillers, and antioxidants. This process is crucial as it determines the physical properties of the final product, including elasticity, durability, and weather resistance.

After compounding, the rubber mixture is formed into specific shapes using molding techniques. This can include compression molding, injection molding, or transfer molding, depending on the desired product characteristics. Each method requires controlled heat and pressure to ensure the material cures properly.

Curing, or vulcanization, is the process of heating the rubber to cross-link the polymer chains. This transforms the rubber from a pliable material into a durable, elastic product. Proper curing is essential for achieving the desired mechanical properties and longevity of rubber products.

Once cured, rubber products often undergo finishing processes, such as trimming, grinding, or surface treatment. These processes help enhance the appearance and performance characteristics of the products before they are packaged and shipped.

Side channel blowers can play a critical role in several stages of the rubber manufacturing process. Their unique design and capabilities make them suitable for various applications, including:

During the compounding phase, side channel blowers can efficiently handle the airflow required for mixing. They ensure a consistent supply of air, which helps maintain optimal temperatures and prevents overheating of materials, thereby enhancing the mixing process.

In the curing phase, controlling the temperature is crucial. Side channel blowers can provide effective cooling solutions, helping to maintain consistent temperatures during vulcanization. This not only ensures uniform curing but also reduces the risk of defects in the final product.

Proper ventilation is essential during molding and finishing processes to remove excess heat and vapors. Side channel blowers can effectively exhaust hot air and fumes, maintaining a safe and efficient working environment. This helps prevent contamination and ensures the quality of the final products.

In rubber manufacturing, fine particles and dust can be generated during processes like grinding and trimming. Side channel blowers can be used in dust collection systems, effectively capturing airborne particles and maintaining a clean workspace.

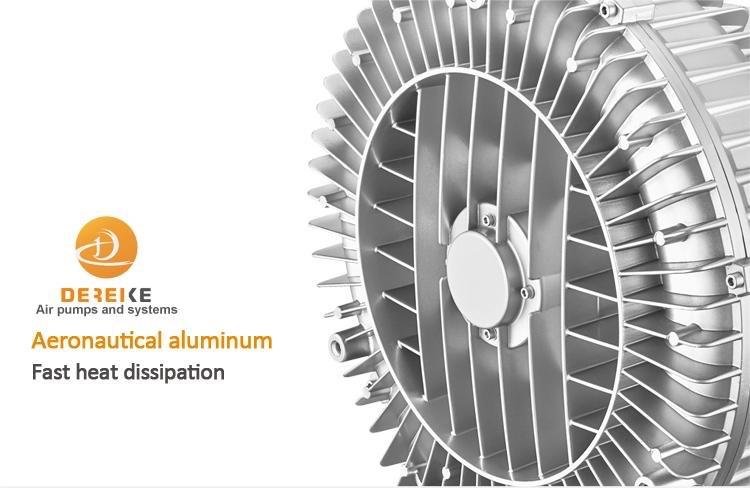

Side channel blowers are known for their high efficiency, delivering consistent airflow with minimal energy consumption. This is particularly beneficial in rubber manufacturing, where maintaining controlled environments can significantly impact production costs.

With fewer moving parts compared to traditional blowers, side channel blowers are generally low-maintenance. This reliability translates to reduced downtime, allowing manufacturers to maintain productivity and efficiency throughout the rubber production process.

The compact design of side channel blowers makes them suitable for integration into existing manufacturing systems without requiring extensive modifications. This flexibility allows manufacturers to optimize their processes without significant capital investment.

Side channel blowers can be easily adapted for various applications within the rubber products industry. Whether for air handling, cooling, or dust control, their versatility ensures they can meet diverse operational needs effectively.

As industries increasingly focus on sustainability, the energy-efficient operation of side channel blowers aligns with environmental goals. By reducing energy consumption and minimizing waste, they contribute to greener manufacturing practices.

The rubber products industry, like hydraulic hose crimper for sale, stands to benefit significantly from the implementation of side channel blowers. Their ability to enhance efficiency, reduce maintenance, and adapt to various processes makes them an invaluable asset in rubber manufacturing. By improving air handling, cooling, and dust control, side channel blowers contribute to the overall quality and sustainability of rubber products.

As the industry continues to evolve, adopting innovative solutions like side channel blowers will be crucial for manufacturers aiming to maintain competitiveness and meet the demands of a dynamic market.