The Permanent Magnet Blower (PMB) is a revolutionary innovation in the blower industry, specifically designed to provide higher efficiency, reliability, and performance in a wide range of industrial applications. Using the latest technology, such as permanent magnet synchronous motors, this blower offers several advantages over traditional blower systems. With an efficiency rate of up to 87%, PMBs are setting new standards for energy-saving, durability, and maintenance-free operation.

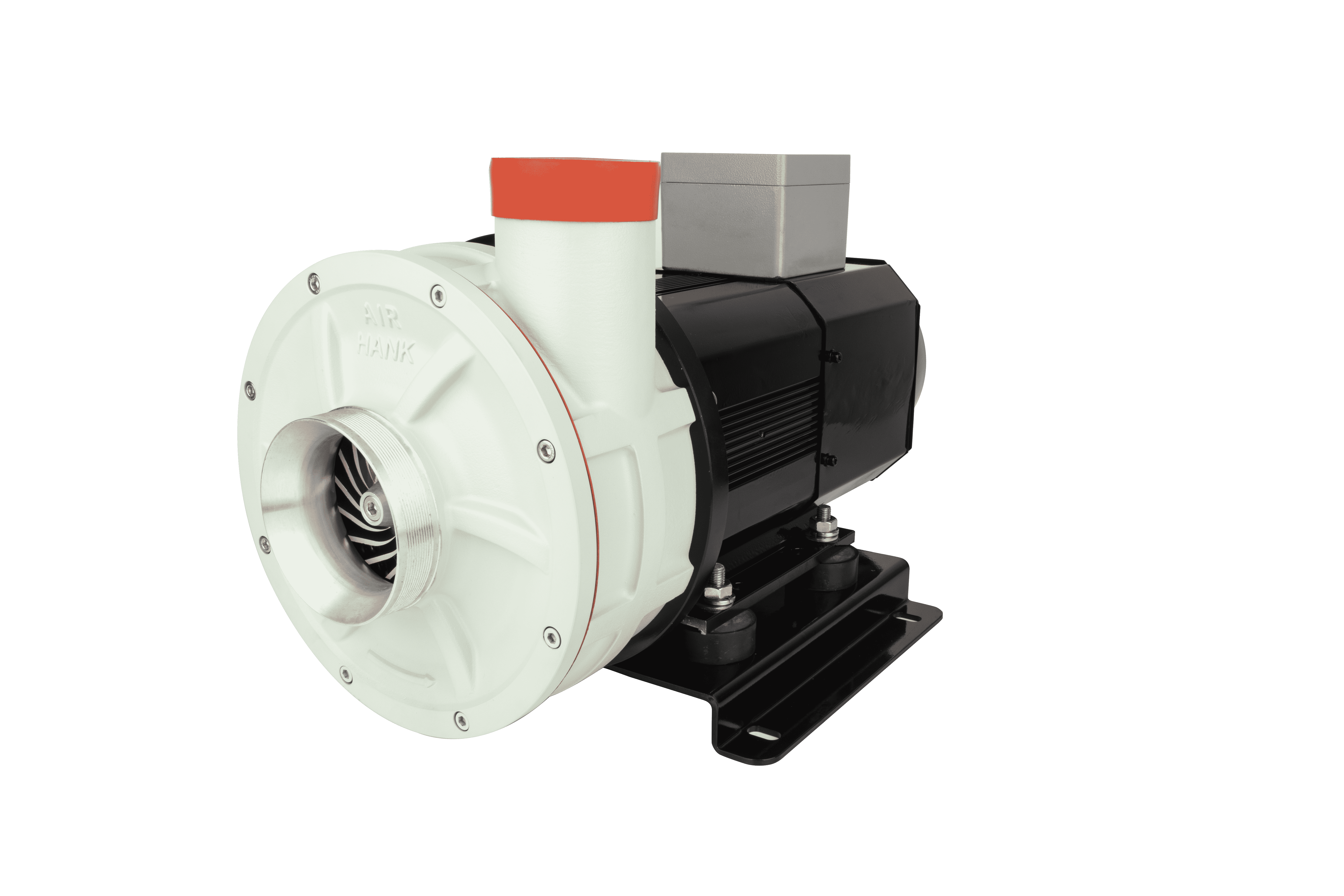

At the core of a Permanent Magnet Blower is the permanent magnet synchronous motor (PMSM), which ensures high-speed performance and excellent energy conversion. The motor directly drives the impeller without the need for a belt, tension pulley, or any other vulnerable components that could wear out over time. This direct structure design minimizes mechanical loss, offering better transmission efficiency and making the system more reliable and longer-lasting.

Additionally, these blowers feature a stepless speed regulation system, which allows for variable speed control ranging from 0 to 600 Hz. This flexibility in operation enables industries to tailor the blower’s performance to specific needs, providing enhanced control over air delivery and efficiency.

The primary benefit of permanent magnet blowers is their exceptional energy efficiency. With efficiencies reaching up to 87%, these blowers significantly reduce power consumption compared to conventional blower systems. The use of a permanent magnet synchronous high-speed motor plays a vital role in minimizing energy loss, ensuring that less power is wasted in the process.

In addition, these blowers consume ultra-low amounts of energy while operating at high speeds, with direct speeds reaching up to 18,000 RPM. This not only reduces operational costs but also aligns with global sustainability goals by lowering carbon footprints.

Another major advantage is the maintenance-free design of permanent magnet blowers. Unlike traditional blowers that rely on belts and other moving parts that require frequent maintenance and replacement, the PMB operates without belts, pulleys, or other vulnerable components. This significantly reduces downtime and maintenance costs, making it ideal for industries where reliability and continuous operation are crucial.

With the direct drive structure, permanent magnet blowers experience less wear and tear, resulting in longer service life and higher operational stability. This reliability is critical in industries like food production, electronics manufacturing, and chemical processing, where downtime can lead to significant financial losses.

Another standout feature is the compact size and lightweight design of the permanent magnet blower. These blowers are typically about 50% lighter and smaller in volume than traditional belt-driven centrifugal fans. This makes transportation, installation, and system integration much easier and more cost-effective. Their compact design is perfect for businesses with limited space or those looking for efficient, high-performance equipment that doesn’t take up too much room.

With the integration of advanced technology, permanent magnet blowers come equipped with real-time monitoring systems. These systems allow for continuous monitoring of key parameters such as speed, frequency, voltage, current, and temperature. This real-time data enables operators to keep a close watch on the blower’s performance, ensuring any potential issues are identified early, minimizing risks, and preventing costly breakdowns.

The ability to operate over a wide frequency range from 0 to 600 Hz gives permanent magnet blowers remarkable flexibility. Industries that require variable airflow, such as those in the food processing, electronics, or chemical industries, can adjust the blower’s speed to match production requirements. This capability provides significant energy savings and better control over the blower’s output, ultimately improving productivity and operational efficiency.

Permanent magnet blowers are versatile machines that can be employed across a variety of industries. Below are some of the most common applications:

In the food industry, Permanent Magnet Blowers are extensively used for drying and cooling processes. These blowers provide precise and consistent airflow, crucial for applications such as drying food products, blowing off water after washing, or assisting in packaging lines to ensure the smooth transfer of products.

Their energy efficiency and maintenance-free design make them an excellent choice for production lines that need to operate around the clock, without frequent interruptions for maintenance.

Another significant application of PMBs is in the drying of electronic components. During the manufacturing process of circuit boards, microchips, or other sensitive electronic parts, excess moisture must be removed to prevent damage or malfunction. Permanent magnet blowers are ideal for this task due to their high-speed capabilities, low energy consumption, and precise control over airflow, ensuring that moisture is efficiently removed without damaging the delicate components.

In industrial facilities, PMBs are often used as part of air supply or exhaust systems. Their high efficiency ensures that they can handle demanding applications like ventilation, air filtration, or dust removal while consuming minimal energy. The ability to adjust airflow as required helps industries meet varying operational demands, making them versatile tools for improving air quality and maintaining optimal working conditions in manufacturing plants.

Special types of permanent magnet blowers can withstand high temperatures, making them suitable for industries that deal with hot gases or require equipment that can operate in extreme heat environments. These blowers can be used in applications such as kiln drying, chemical processing, and other high-temperature operations where standard blowers might fail.

The Permanent Magnet Blower is a game-changing technology in the blower industry, offering unparalleled advantages in terms of efficiency, maintenance, energy consumption, and operational flexibility. Its wide range of applications, from food production lines to electronics manufacturing, makes it an invaluable tool for many industries seeking to improve their productivity while reducing costs.

With its ability to operate in high-temperature environments, real-time monitoring capabilities, and long service life, the permanent magnet blower is paving the way for more sustainable and reliable industrial processes. As industries continue to push for greater efficiency and sustainability, PMBs will undoubtedly play an increasingly vital role in meeting these demands.

上一篇:IP Level for Side Channel Blower

下一篇:没有了