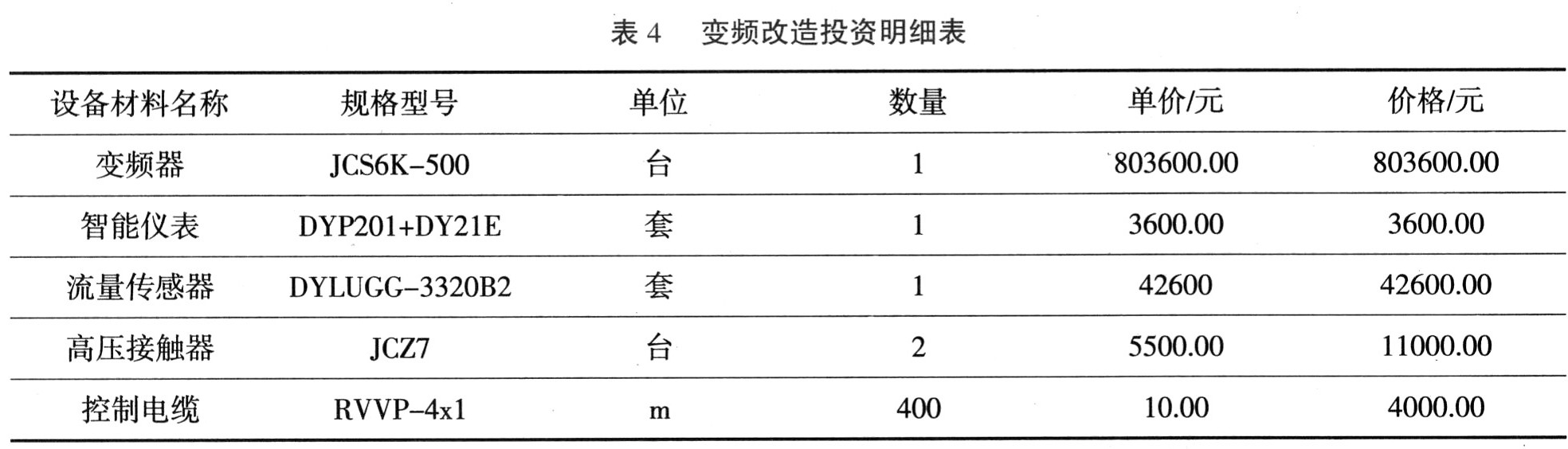

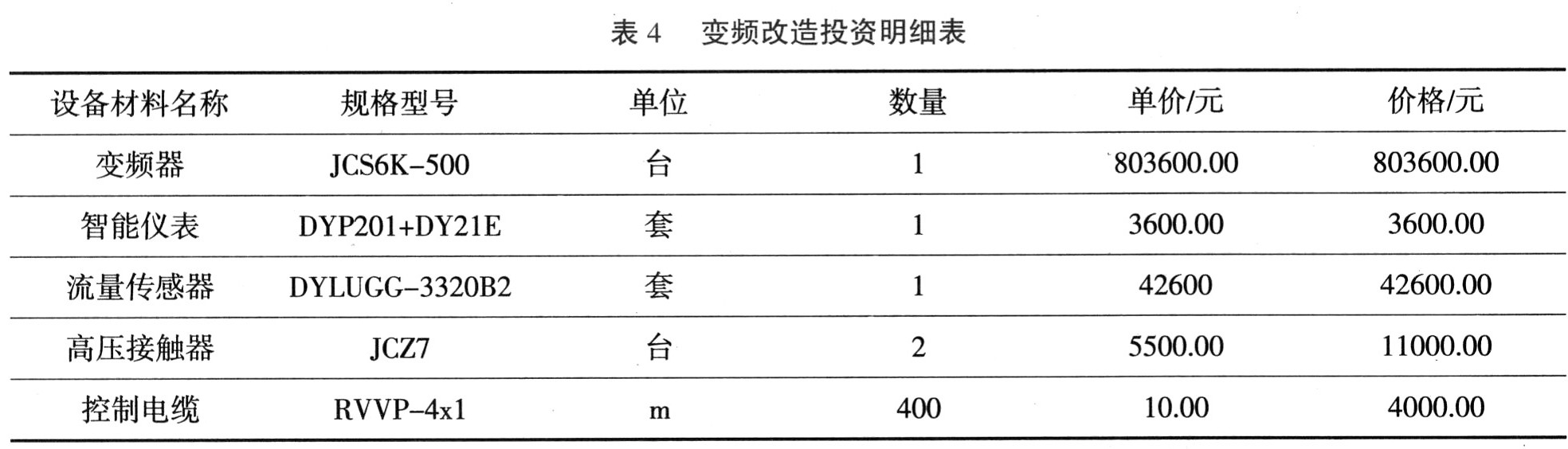

The investment composition of single fan frequency conversion transformation is listed in Table 4.

Because of the large one-time investment of "the application scheme of high voltage frequency conversion technology on D450 fan", we hope to transform one of the fan's electrical system first. After the project is completed, the system runs for 3 to 6 months, and then the operation of the frequency conversion device is observed, and then the other fan is transformed.

From formula (15): Feasibility analysis of energy-saving application of high voltage frequency conversion technology on D450 fan, fan efficiency is 70%, motor efficiency is 75%. According to the current operating parameters of 2 # and 3 # fans, energy-saving estimation is made after frequency conversion transformation as follows.

5.1 2 # Energy Saving Budget of Fan

According to the calculation of the annual running time of the fan of 8640 hours, the annual energy consumption before the transformation of frequency conversion and energy saving was 1876,600 kW h, and the annual total electricity consumption was 1876,600 kW hxO.42 yuan/kW H = 788,200 yuan.

After energy-saving transformation by frequency conversion, the energy-saving rate is estimated at 36%, and the annual electricity cost can be saved by 788,200 yuan x 36% = 283,800 yuan.

The payback period of investment: 864,800 yuan/283,800 yuan = 3.0 years.

5.23 # Energy Saving Budget of Fan

According to the annual running time of the fan of 8640 hours, 153.545 million kW.h. was consumed in the year before the transformation of frequency conversion energy-saving, and the annual total electricity consumption was 153.540 million kW.h * 0.42 yuan/kwh = 644.9 million yuan.

After energy-saving transformation by frequency conversion, the energy-saving rate is estimated at 4l%. The annual electricity cost can be saved by 644,900 yuan x 4l%=264,400 yuan.

The payback period of investment is 864,800 yuan/264,400 yuan = 3.3 years.

6 Conclusion

Through understanding the working conditions of D450 fan, testing the operation parameters and energy saving analysis, the following results will be achieved after the frequency conversion transformation of D450 fan system.

(1) The working condition is improved, the efficiency is improved and the electric energy is saved.

When the system is put into the converter, the windshield need not be adjusted, and the frequent starting and stopping of the motor are avoided.

(2) Improve the degree of automation of the system, the frequency converter automatically adjusts the speed according to the demand, effectively improve the indoor environment, save a lot of electricity;

(3) The operation parameters of the equipment have been improved and the system efficiency has been greatly improved.

(2) Maintenance of the system has been greatly reduced and maintenance costs have been reduced.

After the system is put into the frequency converter, the maintenance period and service life of the pipeline are prolonged.

(2) After the system is put into the converter, the motor starts smoothly and steadily, and the speed reduces, which reduces the cost of motor repair and effectively prolongs the maintenance period of the equipment.

(3) Reduce the impact on the power grid when starting: after the system is put into the frequency converter, the motor realizes soft start and soft stop, which correspondingly reduces the impact on the power grid.

Through the application analysis of D450 fan working condition grounding and high voltage frequency conversion technology in D450 fan, this scheme is feasible.

Because of the large one-time investment of "the application scheme of high voltage frequency conversion technology on D450 fan", we hope to transform one of the fan's electrical system first. After the project is completed, the system runs for 3 to 6 months, and then the operation of the frequency conversion device is observed, and then the other fan is transformed.

Because of the large one-time investment of "the application scheme of high voltage frequency conversion technology on D450 fan", we hope to transform one of the fan's electrical system first. After the project is completed, the system runs for 3 to 6 months, and then the operation of the frequency conversion device is observed, and then the other fan is transformed.