In today’s industrial sector, reducing operating costs without compromising efficiency is a top priority. Side channel blowers have emerged as a cost-effective alternative to traditional systems, offering superior energy efficiency and long-term savings.

Their unique impeller design generates high-pressure airflow with lower power consumption—ideal for applications like pneumatic conveying, wastewater treatment, and industrial vacuum systems. Compact, durable, and low-maintenance, these blowers provide a practical solution for industries aiming to cut costs while maintaining performance.

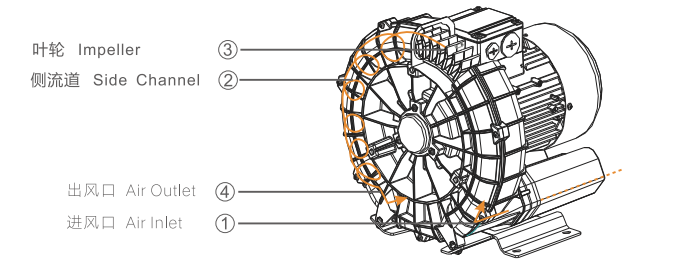

Side channel blowers, also known as regenerative blowers, operate on a unique principle that sets them apart from other types of blowers. They consist of a dynamically balanced impeller rotating inside a stator housing. As the impeller rotates, it traps air between its blades and the housing, creating a series of vortex motions. These vortices amplify the air pressure in each stage, allowing the blower to achieve high pressure and vacuum levels without the need for oil or other lubricants.

The working principle is based on the transfer of energy from the rotating impeller to the air molecules. This process generates both pressure and vacuum in a single unit, making side channel blowers versatile for various applications such as aeration, vacuum lifting, and material handling.

Side channel blowers offer several distinct features that make them an ideal choice for industrial applications:

Oil-Free Operation: Unlike traditional blowers that require lubrication, side channel blowers operate without oil, reducing maintenance costs and the risk of contamination in sensitive applications.

High Efficiency: Due to their unique design, side channel blowers can generate higher pressure levels with lower energy consumption compared to conventional blowers.

Quiet Operation: These blowers are known for their low noise levels, making them suitable for applications where noise reduction is crucial.

Compact Design: The compact and lightweight design allows for easy installation in various settings, saving space and reducing installation costs.

Durability and Reliability: Built with high-quality materials, side channel blowers are designed to withstand harsh conditions, ensuring long-term reliability and reduced downtime.

One of the most significant advantages of using side channel blowers is their energy efficiency. Traditional blowers, especially those using oil-based mechanisms, tend to consume more power due to friction losses and the need for regular lubrication. In contrast, side channel blowers operate on a frictionless principle, reducing energy consumption significantly.

For instance, a manufacturing plant that switches from oil-based blowers to side channel blowers could see a reduction in energy consumption by up to 30%. This translates to substantial cost savings over time, particularly in energy-intensive industries such as chemical processing, wastewater treatment, and food and beverage production.

Another cost-saving benefit of side channel blowers is their minimal maintenance requirements. Traditional blowers require regular lubrication, filter changes, and component replacements, which can add up in terms of both time and money. Side channel blowers, with their oil-free operation and durable design, require far less maintenance.

For example, a packaging company that previously used oil-lubricated blowers reported a 40% reduction in maintenance costs after switching to side channel blowers. Additionally, the decreased need for maintenance means less downtime, leading to higher productivity and profitability.

Let's take a closer look at how side channel blowers stack up against traditional oil-based blowers in terms of cost efficiency:

Energy Consumption: Side channel blowers use significantly less energy due to their high-efficiency design. Oil-based blowers, on the other hand, lose energy through friction and require more power to operate.

Maintenance Costs: Oil-based blowers need regular oil changes, filter replacements, and component servicing. Side channel blowers are virtually maintenance-free, saving both time and money.

Operational Costs: The total cost of ownership for side channel blowers is much lower due to reduced energy consumption and maintenance needs. Businesses can achieve a return on investment (ROI) in a shorter time frame compared to oil-based blowers.

Side channel blowers are not just limited to one type of application; they are versatile and can be used across various industries. Here are some of the most common applications:

Aeration in Water Treatment Plants: Providing oxygen to water in treatment processes, side channel blowers ensure effective aeration while keeping energy consumption low.

Vacuum Lifting in Packaging: In the packaging industry, these blowers are used for vacuum lifting and material handling, enhancing efficiency and reducing operational costs.

Air Supply in Combustion Processes: Side channel blowers provide consistent air supply for combustion processes in industrial furnaces, improving fuel efficiency and reducing emissions.

Pneumatic Conveying in Food Processing: They are also used for conveying food products and grains without contamination risks, thanks to their oil-free operation.

Another benefit of side channel blowers is their adaptability to various operational requirements. Businesses can choose from a range of models with different pressure and vacuum capabilities, ensuring they get a solution tailored to their specific needs. Moreover, the blowers can be equipped with accessories such as silencers and filters to meet stringent operational standards.

Switching to side channel blowers not only reduces costs but also benefits the environment. With lower energy consumption and oil-free operation, these blowers contribute to a smaller carbon footprint and reduced waste generation. For companies looking to improve their sustainability metrics, side channel blowers offer a practical and effective solution.

The bottom line? Side channel blowers deliver real cost savings without compromising performance. Their energy-efficient operation and minimal maintenance needs make them a smart choice for industries ranging from manufacturing to wastewater treatment. What many operators discover is that making the switch doesn't just cut expenses - it often improves overall system reliability.

For businesses looking to boost their bottom line while future-proofing their operations, these blowers represent one of those rare upgrades that pays for itself. The numbers speak for themselves: lower energy bills, reduced downtime, and better long-term performance. It's not often you find a solution that saves money while actually improving your operation, but that's exactly what these systems deliver.